Introduction

The Ammonium Chlorate Manufacturing Plant Project Report serves as a detailed resource for understanding the technical, financial, and operational aspects of setting up a manufacturing facility for ammonium chlorate. Ammonium chlorate, a highly reactive compound, is primarily used in agriculture as a defoliant, in pyrotechnics, and for research purposes in chemical laboratories. Its demand is influenced by industrial and agricultural applications, making it an important compound in the chemical industry. This report explores the manufacturing process, market potential, and crucial considerations for establishing an Ammonium Chlorate Manufacturing Plant .

1. Overview of Ammonium Chlorate

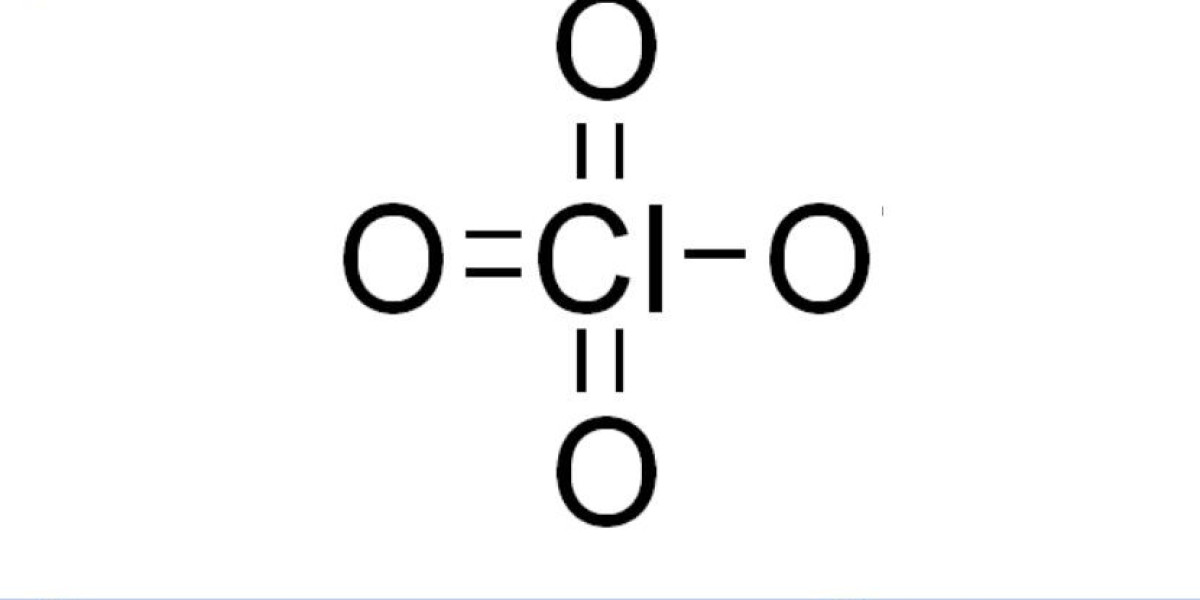

Ammonium chlorate (NH₄ClO₃) is a chemical compound formed by the reaction of ammonium salts and chlorates. Due to its oxidizing properties, it is primarily used in specific industrial and agricultural applications.

Applications of Ammonium Chlorate:

- Agriculture : Used as a defoliant in farming to aid in the harvesting process.

- Explosives and Pyrotechnics: Plays a role in creating explosive materials and fireworks.

- Chemical Research: Used in laboratories for research and development purposes.

Due to its reactive nature, ammonium chlorate production and handling require stringent safety measures and compliance with regulations.

Get a Free Sample Report with Table of Contents@

2. Market Potential and Demand

The market for ammonium chlorate is driven by its applications in agriculture, chemical research, and controlled explosive materials.

Key Market Drivers

- Agricultural Sector: Increasing demand for defoliants to enhance crop harvesting efficiency boosts ammonium chlorate usage.

- Industrial Applications: Demand in pyrotechnics and controlled explosives drives market growth.

- Research and Development: Use in laboratories for specific chemical reactions and studies supports its demand.

Although ammonium chlorate has niche applications, its market is steady, with demand concentrated in specialised industries.

3. Ammonium Chlorate Manufacturing Process

The production of ammonium chlorate involves chemical synthesis under controlled conditions to ensure product quality and safety.

Raw Materials

- Ammonium salts (e.g., ammonium hydroxide).

- Chlorates (e.g., sodium chlorate or potassium chlorate).

Production Process

- Reaction: Ammonium salts react with chlorates in an aqueous solution to form ammonium chlorate.

- Filtration: Impurities are removed through filtration to ensure product purity.

- Crystallisation: The solution is cooled to allow ammonium chlorate crystals to form.

- Drying and Packaging: Crystals are dried and packed in moisture-proof containers to maintain stability and quality.

Safety Considerations

Due to its high reactivity and explosive potential, ammonium chlorate manufacturing requires advanced safety protocols, including temperature control and minimisation of friction during processing.

4. Key Considerations for Plant Setup

Location Selection

The plant should be located in industrial zones with access to raw materials and transportation networks, away from residential areas to ensure safety.

Infrastructure and Equipment

- Reactors: For the chemical synthesis of ammonium chlorate.

- Filtration Units: To remove impurities from the product.

- Crystallisation Equipment: For forming high-quality ammonium chlorate crystals.

- Safety Systems: Fire suppression and temperature monitoring systems to mitigate risks.

Regulatory Compliance

Due to its explosive nature, ammonium chlorate manufacturing requires adherence to strict safety and environmental regulations. Permits and certifications from local authorities are mandatory.

Skilled Workforce

Trained personnel are essential for handling reactive chemicals and ensuring the safe operation of the plant.

5. Financial Aspects of the Project

Capital Investment

- Land and Infrastructure : Costs depend on the size and location of the facility.

- Machinery : Advanced equipment for synthesis, filtration, and crystallization.

- Safety Measures : Investment in fire suppression systems and protective gear.

operating costs

- Raw Materials : Ammonium salts and chlorates form the primary inputs.

- Energy Costs : The production process requires continuous power supply and temperature regulation.

- Labor Costs : Salaries for skilled operators and safety personnel.

revenue potential

Revenue depends on the scale of production and market demand in industries such as agriculture, pyrotechnics, and research. Ammonium chlorate's niche applications ensure steady demand, although market size is relatively smaller compared to other chemicals.

6. Challenges in Ammonium Chlorate Manufacturing Safety Risks

The reactive nature of ammonium chlorate poses safety challenges during production, storage, and transportation. Adopting stringent safety protocols is essential.

Regulatory Hurdles

Compliance with strict safety and environmental regulations can be time-consuming and costly. Regular audits and certifications are required.

Limited Applications

The niche market for ammonium chlorate restricts its widespread demand, making it essential for manufacturers to target specific industries effectively.

FAQs

1. What are the main uses of ammonium chlorate?

Ammonium chlorate is used in agriculture as a defoliant, in pyrotechnics, and in chemical laboratories for research purposes.

2. What is the production process for ammonium chlorate?

It involves the reaction of ammonium salts with chlorates, followed by filtration, crystallization, and drying under controlled conditions.

3. What safety measures are required in ammonium chlorate production?

Temperature control, fire suppression systems, and adherence to strict handling protocols are critical due to its high reactivity and explosive nature.

4. What industries drive the demand for ammonium chlorate?

Industries such as agriculture, pyrotechnics, and chemical research drive its demand.

5. How much investment is required for an ammonium chlorate manufacturing plant?

Investment depends on the scale of production, covering costs for land, equipment, safety systems, and raw materials.

6. What are the challenges in ammonium chlorate manufacturing?

Challenges include safety risks, regulatory compliance, and the niche nature of its market applications.

7. Is ammonium chlorate manufacturing profitable?

Yes, it can be profitable when targeted towards specialized industries like agriculture and pyrotechnics, which have consistent demand.

Media Contact

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — USA

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA