In the industrial world of orange sorting systems, the functionality of every component plays a pivotal role in ensuring smooth operations. One often-overlooked but crucial part of this system is the Door Hinge For Orange Sort Of. These hinges allow easy access to sorting machines, enabling maintenance, repair, and cleaning. However, choosing the right door hinge can be challenging, as it requires a combination of factors such as durability, material, weight capacity, and environmental considerations. In this article, we will explore the top considerations when selecting a door hinge for orange sort applications.

The Role of a Door Hinge in Orange Sort Systems

Before diving into the specific considerations for selecting a door hinge for orange sort applications, it is important to understand its role in the system. Orange sorting machines are essential in sorting citrus fruits based on their size, quality, and color. These systems include doors that protect the machinery and allow operators to easily access and maintain the equipment.

A door hinge enables the easy opening and closing of these doors, allowing for proper ventilation, access, and repairs. The door hinge must be durable enough to withstand the heavy use associated with industrial environments. If the hinge fails, it can cause downtime, inefficiency, and potential safety hazards. Therefore, it is essential to choose the right hinge that suits the specific needs of orange sorting operations.

1. Material Durability and Corrosion Resistance

One of the first considerations when selecting a door hinge for orange sort applications is the material of the hinge. Sorting systems are often used in environments that involve exposure to moisture, dust, and chemicals, all of which can lead to corrosion over time. Therefore, the hinge material must be able to withstand these harsh conditions without losing its strength.

Popular Material Options

Stainless Steel: Stainless steel is the most popular material for door hinges in industrial environments due to its excellent corrosion resistance. It performs well in humid or wet environments, making it ideal for orange sorting systems, where exposure to moisture is common.

Galvanized Steel: Galvanized steel, which has a protective zinc coating, is another material option. It offers a lower cost alternative to stainless steel while still providing good resistance to corrosion. However, it may not offer the same level of long-term durability.

Brass: Brass is another option, though it is less commonly used for heavy-duty applications. Brass has moderate resistance to corrosion and is often used for aesthetic reasons. However, it may not be as resilient as stainless steel in demanding environments.

Aluminum: Aluminum hinges are lightweight and resistant to rust, making them suitable for environments with minimal exposure to moisture. However, they are not as durable as stainless steel hinges and may be more prone to wear and tear under heavy use.

The material of the door hinge for orange sort applications plays a significant role in determining the lifespan of the hinge. It is essential to select a material that can endure the specific challenges faced by orange sorting systems.

2. Weight Capacity and Door Size

The size and weight of the door are crucial factors when choosing a door hinge for orange sort applications. Sorting doors can be large and heavy, especially when they are made to accommodate large machinery and frequent usage. The hinge needs to be able to support the door’s weight and allow for smooth operation without compromising functionality.

Considerations for Weight and Size

Load-Bearing Capacity: The hinge must be capable of supporting the weight of the door. It’s important to choose a hinge that can handle the weight of the door without risk of breaking or wearing down prematurely. The weight capacity is typically listed in the hinge specifications.

Multiple Hinges: For heavier doors, more than one hinge is often necessary. Typically, doors over a certain weight, such as 50 kg, will require two or three hinges to evenly distribute the weight. Using multiple hinges prevents undue stress on the door and hinge.

Hinge Size: The size of the hinge should also match the dimensions of the door. A small hinge on a large door will be ineffective, causing it to wear out quickly. Conversely, an oversized hinge can lead to unnecessary costs and may be impractical. Make sure to select a hinge that is properly sized for the door’s dimensions.

3. Hinge Design and Functionality

The design of the hinge is an important factor in determining how well it will function in the orange sort system. Different hinge designs offer different benefits, so selecting one that aligns with the operational needs of the sorting system is essential.

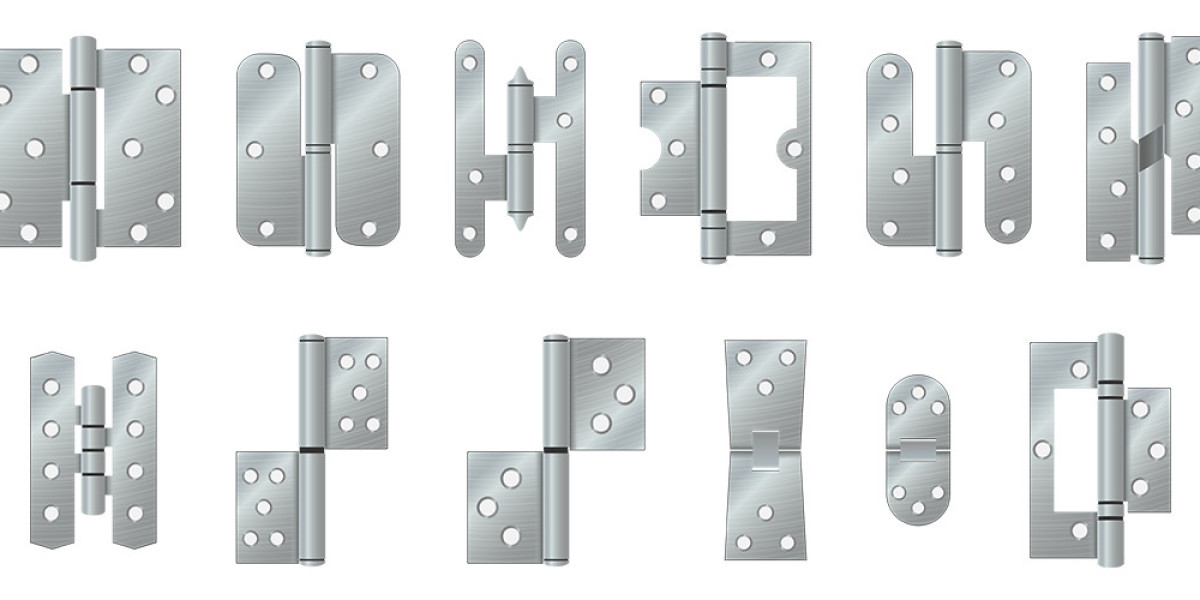

Common Hinge Designs

Butt Hinges: These are the most traditional and commonly used hinges for doors. They consist of two interlocking plates that allow the door to swing open and closed. Butt hinges are typically used for medium-sized doors and are easy to install, making them ideal for many industrial applications.

Continuous Hinges: Also known as piano hinges, these run the full length of the door. Continuous hinges are ideal for heavy doors, as they distribute the weight evenly across the door. They are particularly useful in environments where doors are subjected to frequent use and heavy loads.

Concealed Hinges: For a clean and seamless look, concealed hinges are often used. These hinges are hidden from view when the door is closed, providing an aesthetically pleasing appearance. While concealed hinges are great for visual appeal, they may not be as durable or robust as other hinge types in demanding environments.

Heavy-Duty Hinges: For larger or heavier doors, heavy-duty hinges are often necessary. These hinges are reinforced with stronger materials and additional support mechanisms, making them ideal for doors used in industrial settings, including orange sort applications.

The hinge design directly affects the door’s movement and functionality, so it’s essential to select a hinge that matches the size, weight, and frequency of use of the orange sort doors.

4. Environmental Factors

Another important consideration when choosing a door hinge for orange sort applications is the environment in which the sorting system operates. The sorting environment is likely to expose the hinge to elements like moisture, dust, chemicals, and temperature fluctuations. The right hinge must be able to withstand these elements without degrading over time.

Key Environmental Factors

Humidity: In areas where the humidity is high, such as in orange sorting systems that involve water or wet fruit, corrosion-resistant materials like stainless steel are essential. Galvanized steel may also be a good option in environments where humidity is moderate.

Chemical Exposure: If the sorting system is exposed to cleaning chemicals or oils, it is important to select a hinge made from materials that are resistant to corrosion from these substances. Stainless steel is known for its resistance to most cleaning chemicals.

Temperature Fluctuations: Temperature fluctuations can cause materials to expand and contract. If the sorting system operates in an area with extreme temperature changes, the selected hinge should be able to tolerate these fluctuations without compromising performance.

Choosing a hinge that can withstand environmental challenges will increase the lifespan of both the hinge and the orange sort applications system.

5. Cost and Long-Term Value

When selecting a door hinge for orange sort applications, it’s important to consider the cost, but also the long-term value. While budget-friendly hinges may seem appealing, they often come with trade-offs in terms of durability and functionality.

Evaluating Cost vs. Durability

Initial Cost: Stainless steel hinges tend to be more expensive initially but offer superior durability and resistance to corrosion. This means fewer repairs and replacements in the long run, which can save you money.

Long-Term Value: While cheaper hinges may seem like a cost-effective solution, they may wear out faster, especially in demanding environments like orange sorting systems. Investing in a high-quality hinge up front may prevent frequent maintenance costs and downtime.

Weighing the cost against the long-term benefits of a durable and reliable hinge will ensure that you make the best choice for your orange sort applications.

Conclusion:

Selecting the right door hinge for orange sort applications is a critical decision that affects the efficiency, safety, and longevity of your sorting system. By carefully considering factors such as material durability, weight capacity, hinge design, environmental conditions, and long-term value, you can ensure that your sorting doors function smoothly and efficiently.

The right hinge will not only improve the performance of your orange sorting system but will also reduce maintenance costs and downtime, allowing your operation to run without interruption. Ultimately, the investment in a high-quality door hinge pays off by providing long-lasting performance, ensuring that your orange sort system remains reliable for years to come. Visit Trending Hub24 to get more information.